Owner-operator BW ESS’ 100MW/331MWh UK Bramley BESS was unique in numerous ways when it came online last year, the first outside China to use Sungrow’s AC block technology.

The Bramley battery energy storage system (BESS) project in Hampshire, England, was developed by Penso Power and acquired by global BESS investment platform BW ESS, which also acquired Penso outright in October 2024.

Enjoy 12 months of exclusive analysis

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Annual digital subscription to the PV Tech Power journal

- Discounts on Solar Media’s portfolio of events, in-person and virtual

Or continue reading this article for free

The project was probably the largest operational BESS in Europe when it entered commercial operations earlier this year and is still the longest-duration large-scale BESS in the UK, at 3.3-hours.

BW ESS’ CTO Nan Jia discussed the project and why it chose Sungrow’s PowerTitan 2.0 AC block technology at an event hosted by the China-based inverter and BESS manufacturer last week (9 April).

‘Choosing the right technology partner was really important’

The first thing to note is that, during construction in August, BW ESS entered into a seven-year toll with the energy trading arm of oil and gas major Shell for its offtake.

Fixed-price tolls are becoming more and more common in the European industry (having existed for some time in the US and Australia), but they present a challenge for the project owners, Jia explained.

“A fixed term contract is good for investors, but it is a challenge for engineers as we know the customer will run the site hard, and the contract has big penalties if the system doesn’t perform,” he said, speaking at Sungrow’s Global Renewable Energy Summit in Hefei, China.

“That made choosing the technology partner really important.”

The Bramley project’s seven-year toll and 2.5-hour capacity market (CM) contract meant it had specific requirements, alongside the usual safety, reliability and cost-effectiveness.

Jia said the technology needed to to be integrated and pre-calibrated to minimise onsite work, future-proofed to fulfil all grid compliance and auxiliary services, have the ability to demonstrate its performance by simulation, and had to be accompanied by a strong engineering team.

Installation was as fast as one hour per cabinet, with the installation team calling it “the most installation-friendly system they experienced,” he said.

The AC block design of the PowerTitan 2.0 means that it has string power conversion systems (PCS) installed within the 20-foot BESS unit. But this creates an extra challenge, or at least concern, for the operator.

He said: “The design meant the project had 792 power conversion systems, which made me nervous at first—how will Sungrow make sure they all respond in time to signals?”

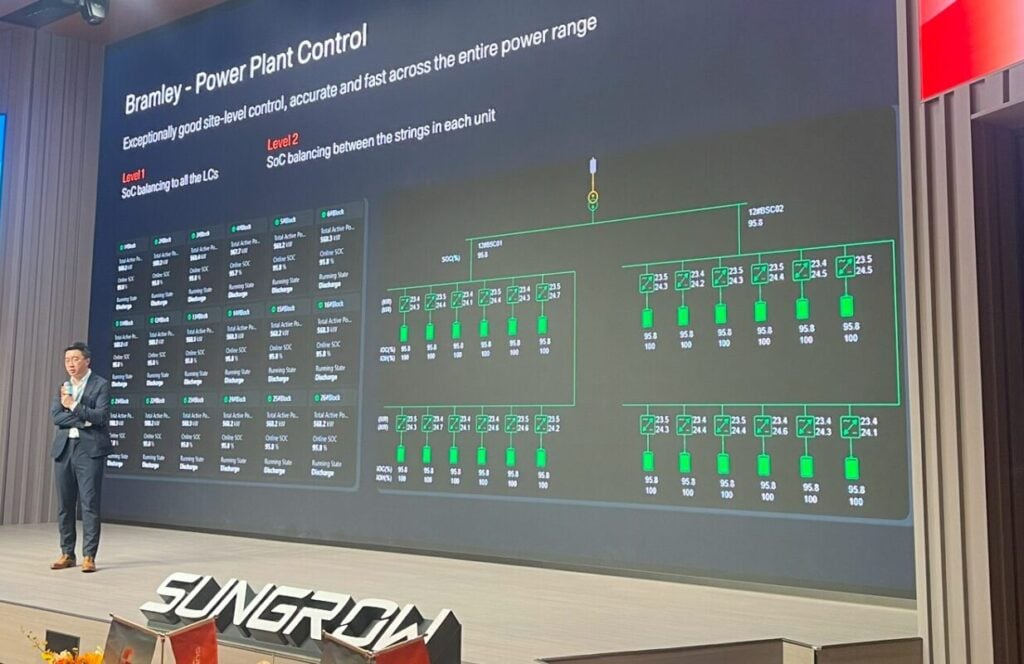

The plant has “exceptionally good” site-level control, proving accurate and fast across the entire power range, he said.

He also explained the PowerTitan 2.0 had two levels of state of charge (SOC) balancing, one for SOC balancing to all the local controllers (LCs) and another for SOC balancing between the strings in each unit.

The system only required one round of charge and discharge for calibration, whilst a system with central inverters would require several, increasing the overall commissioning time.

It is generally harder to measure the SOC for lithium iron phosphate (LFP) batteries than for nickel manganese cobalt (NMC) ones, and LFP is now the dominant cell chemistry used for BESS.

The new kind of SOC calibration was like “going from driving a manual combustion engine car to an automatic or an electric vehicle (EV),” he said. “We had very consistent charging and discharging across the SOC range, which everyone was very happy with.”

Along with other features, that meant that the overall commissioning time took two weeks, whereas a similar sized project with conventional DC blocks and large central inverters could have taken as long as four months, he added.

To conclude, he said the full-site cell-level monitoring, analysis and diagnosis ‘gave everyone a good night’s sleep’.

Jia’s colleague Roberto Jimenez, executive director, discussed the Bramley toll and the industry’s wider move to tolls in an interview with ESN Premium in August last year. BW ESS is part of the shipping and energy conglomerate BW Group.

AC blocks growing in popularity

AC blocks are growing in significance in the BESS industry, with other system integrators such as Wartsila and Fluence following in Sungrow and Tesla’s footsteps and launching PCS-integrated BESS unit products.

Alongside the quicker installation, AC blocks also have the potential to offer better control and monitoring, as BW ESS said Sungrow’s does.

The ease of installation makes it easier for companies like Sungrow to sell in directly to engineering, procurement and construction (EPC) firms rather than having a system integrator as the go-between.

However, they are unlikely to become the industry standard as they are not necessarily suitable for all projects.

DC blocks typically allow for a more flexible configuration for a site particularly when it comes to augmenting projects with additional capacity further down the line. AC block projects also typically have a higher capex than DC block ones, even when accounting for the much quicker installation time.